Retrofit Project for Scrubber & BWTS

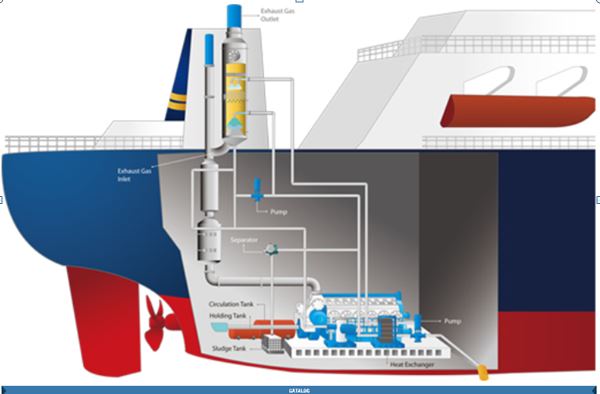

Scrubber

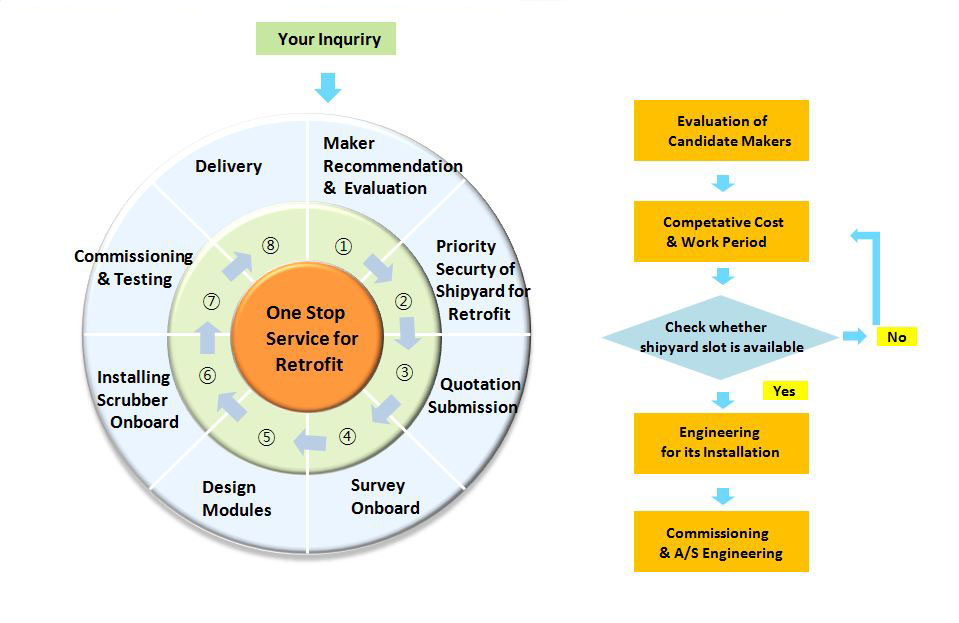

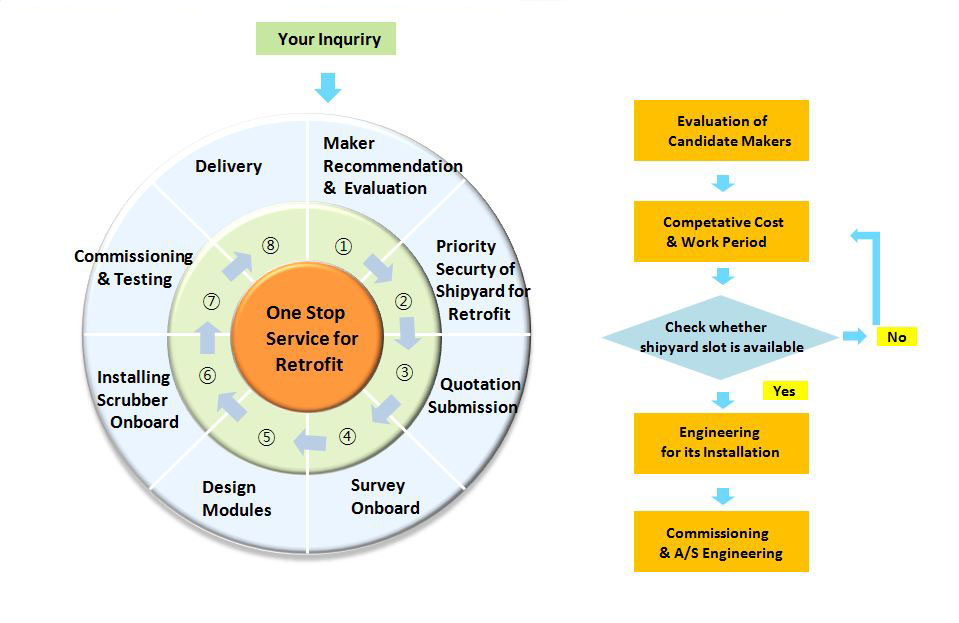

HESCO offers the one stop services for Scrubber projects which have driven owners to consider installation of such systems on the vessels of their fleet based on the calculated future profit margins. since its success is largely dependent on its workforce and technic. HESCO provides clients around the world with skillful, properly trained and highly competent workers. We have the capability & network to provide all these services for Scrubber projects with Scrubber's makers and repair shipyard .

1. Technology review & provide required information

- Review of information and preparation of a technical and commercial evaluation

- System’s description and details

- Plant physical size and integration with existing arrangement and systems

- Evaluation of installation’s feasibility

- Listing of advantages and disadvantages of the installation of the equipment of each Maker

- Providing comparison tables based on Efficacy results of each Maker

- Competative Cost & Work Period

- Check Availibity of Shipyard Berth for Retrofit

- Survey onboard

- 3D Laser Scanner

- Drawings onboard Ship ( P & ID Diagram, Electric Wiring Diagram)

- System Operation Test

- Testing functions

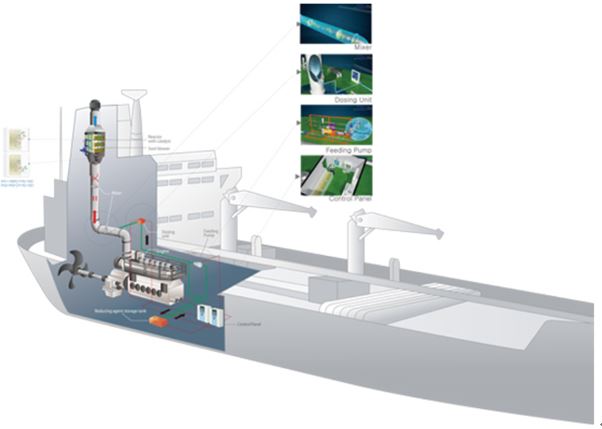

BWTS

HESCO has been performing engineering studies for one finally selected system per ship, based on best possible solution and onboard survey results. It includes the complete proposal with the ballast water treatment system modeled, the piping routing (including piping isometric drawings, materials and parts list), the specification of structure, outfitting modifications and Class required drawings.

1. Technology review & provide required information

- Review of information and preparation of a technical and commercial evaluation

- System’s description and details

- Plant physical size and integration with existing arrangement and systems

- Evaluation of installation’s feasibility

- Listing of advantages and disadvantages of the installation of the equipment of each Maker

- Providing comparison tables based on Efficacy results of each Maker

- Competative Cost & Work Period

- Check Availibity of Shipyard Berth for Retrofit

- Survey onboard

- 3D Laser Scanner

- Drawings onboard Ship ( P & ID Diagram, Electric Wiring Diagram)

- System Operation Test

- Testing functions